Determination of frost resistance in accordance with DIN EN 12371:2010-07

reading time - 4 minINFO series natural stone tests

Assessing the durability of natural stone: the importance of frost resistance testing in accordance with DIN EN 12371:2010-07

Testing frost resistance has a major influence on the assessment of the durability of natural stone. According to current standards, DIN EN 12371:2010-07 is applied here. Frost damage occurs when water penetrates the surface of natural stone. The water freezes with an increase in volume and the existing pore space is not sufficient to withstand the ice pressure. This can lead to spalling, cracks or similar damage.

Natural stone testing: Technological testing and identification testing

During the test, the natural stone samples are alternately frozen in air and thawed in water. Typically, 56 cycles are carried out for floor coverings and 14 freeze-thaw cycles for use in façades.

The test standard distinguishes between a technological test and an identification test. The technological test is used to assess the performance of natural stone as a result of freeze-thaw cycles. In most cases, this is carried out by testing the compressive or flexural strength. In contrast, the identification test is carried out until the natural stone sample fails, but up to a maximum of 168 cycles.

Technological testing

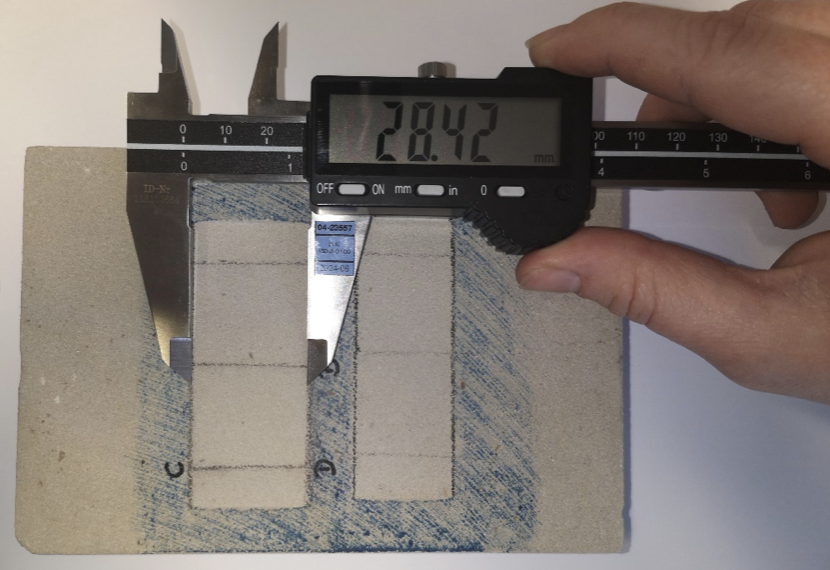

Test specimens are required for the test, which can also be used later to determine the performance. Test specimens with the dimensions (300 x 50 x 50) mm or (70 x 70 x 70) mm are preferred. Other dimensions are possible, but must comply with the standards for determining flexural and compressive strength. At least 21 test specimens are selected from the same batch of natural stone. 10 specimens are subjected directly to the flexural or compressive strength, ten others are subjected to the freeze-thaw cycle and one specimen is used to monitor the core temperature during the test. A hole with a depth of at least 25+5 mm must be drilled into this test specimen and a measuring probe inserted, which must be protected from water ingress.

Implementation of the audit

Before the freeze-thaw cycle begins, the test specimens are dried to constant mass and then prepared for pre-storage. This involves progressive capillary immersion of the specimens in water, initially up to half, then up to three quarters and finally completely, within 2 hours. The specimens then remain in the water bath for around 48 hours before the actual freeze-thaw cycle begins. The test specimens and the temperature element are then installed at a sufficient distance from each other in the preferably automatic climate chamber. A freeze-thaw cycle comprises a six-hour freezing and thawing period. It is important that the core temperature of the monitored test specimen reaches the lowest temperature of -8 to -12 °C and the highest temperature of +5 to +20 °C in each cycle.

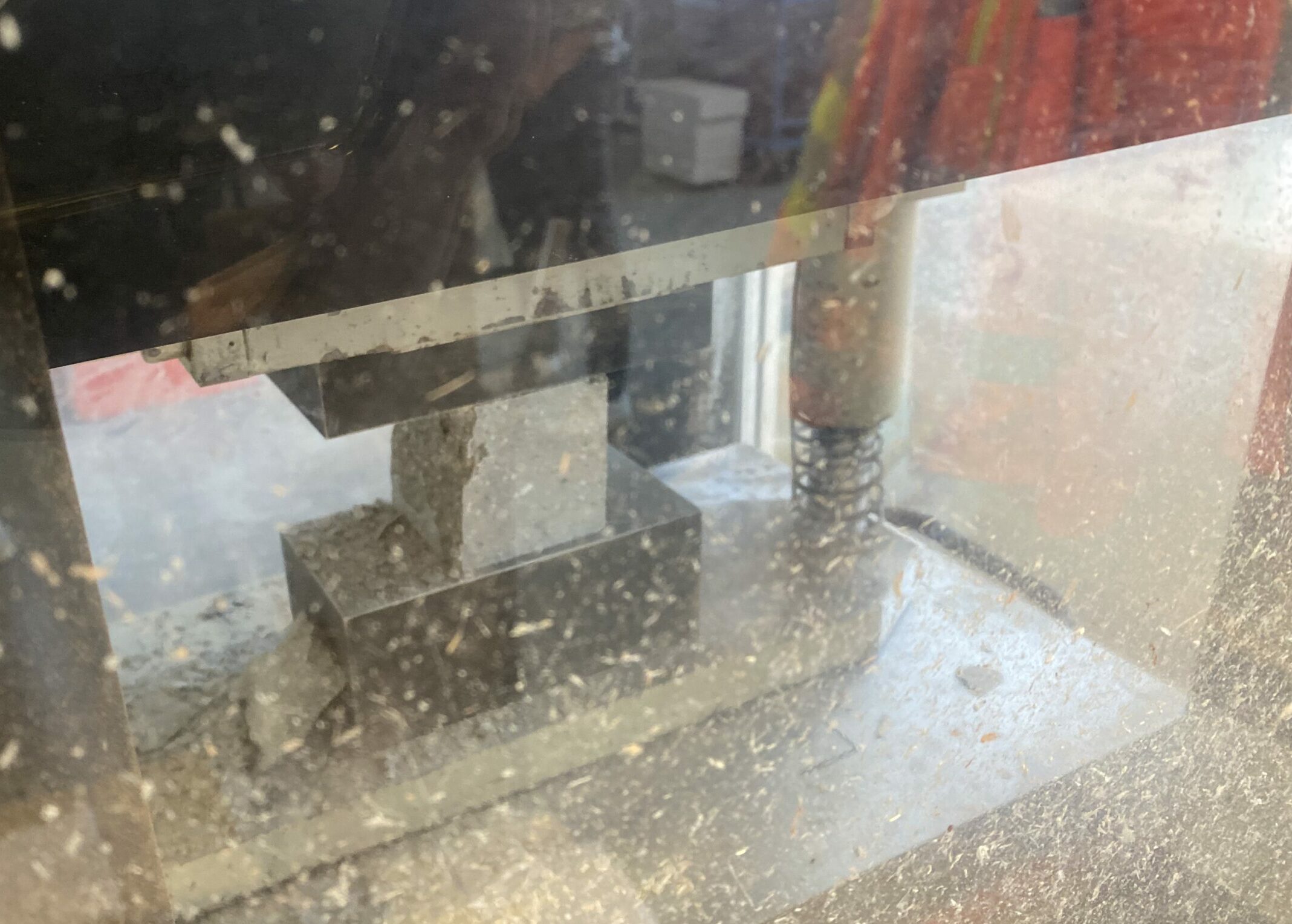

After the required number of freeze-thaw cycles, the test specimens are removed from the climate chamber, dried and inspected for visual damage. The tests on the performance stability of the natural stone are then carried out. The change in flexural and compressive strength is shown as a percentage. The durability of the individual natural stone varieties is assessed in accordance with the applicable product standards and technical delivery conditions.

An example: TL Pflaster-StB 06/15 applies to the use of construction products for the production of paving slabs, slab coverings and edgings, according to which the change in the bending and compressive strength performance characteristics should not be greater than 20%.

Further information

If you have any further questions or would like individual support for your project, please feel free to contact us at any time via our contact form or send us a message to mail@besco-gmbh.de. We will get back to you shortly.

Take a look at past parts of the natural stone tests and find out more about tests for water absorption, flexural strength and compressive strength. Further exciting content awaits you in upcoming articles in the INFO series on natural stone testing.

We would be happy to inform you about the latest

topics and innovations relating to natural stone.

ARTICLES ABOUT THIS TOPIC

reading time – 5 min

reading time – 8 min

reading time – 5 min

reading time – 5 min

reading time – 3 min

reading time – 5 min

reading time – 5 min

reading time – 4 min

reading time – 4 min

reading time – 2 min