Determination of compressive strength according to DIN EN 1926:2007-03

reading time - 4 minINFO-Series Natural Stone Tests

One of the most important physical properties of natural stone is its compressive strength. It is defined as the resistance of a material or building material to compressive forces and is given as the ratio of the breaking force to the cross-sectional area of a specimen.

If natural stone is used outdoors, e.g. in accordance with the DIN EN 1341 and DIN EN 1343 standards or as a hydraulic construction stone, DIN EN 1926:2007-03 must be applied as the test standard. If the natural stone is to be used as a masonry block in accordance with DIN EN 772- 6, a different test standard must be selected.

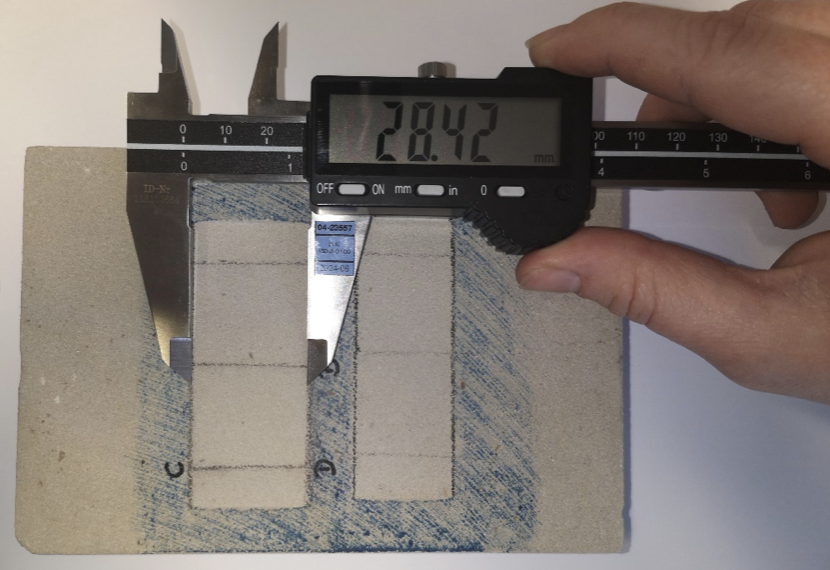

Any determination of compressive strength requires very careful specimen preparation. Specimens in the shape of a cube or cylinder with 70 mm or 50 mm edge lengths or 70 mm or 50 mm diameter and height must be used. The deviations may not be greater than +/- 5 mm. Intermediate sizes are therefore not permitted. The 10 specimens to be tested are checked in advance for flatness and plane parallelism.

The sides of the specimens must also be smooth and may not have any major breakouts. If the geometry requirements specified in the standard are not met, the specimens must be ground, adjusted with mortar or, in the worst case, excluded from the test. It should also be noted here that “pretty”, i.e. extra cleanly chamfered edges on the test specimens are not helpful and must also be grinded again.

It is important for the testing laboratory to specify the anisotropy plane (layering) of the stone to be tested. We, as the client, are obliged to clearly mark this, as it is often hardly visible to the human eye. If the stone is to be tested parallel to the anisotropy planes as well as perpendicular to them, another set of specimens must be tested. (see Fig. 1 and Fig. 2 from DIN EN 1926).

Before testing, the specimens must be dried at 70 °C until mass constancy is reached. This is achieved when the difference in mass of two weighings within approx. 24 h is not greater than 0.1 %.

If the natural stones are to be used as hydraulic construction stone, the specimens are to be stored in water for 48 h and then tested immediately.

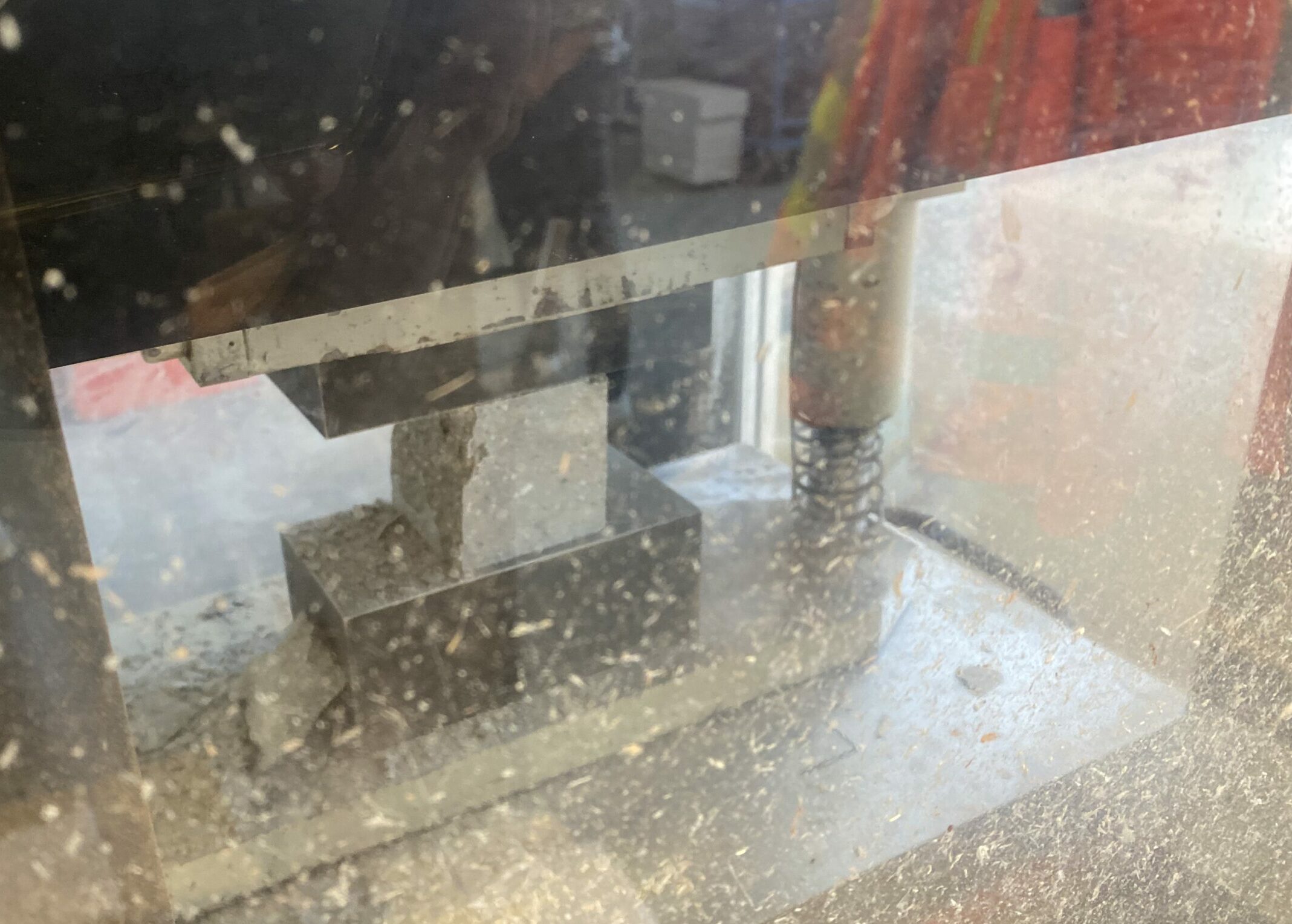

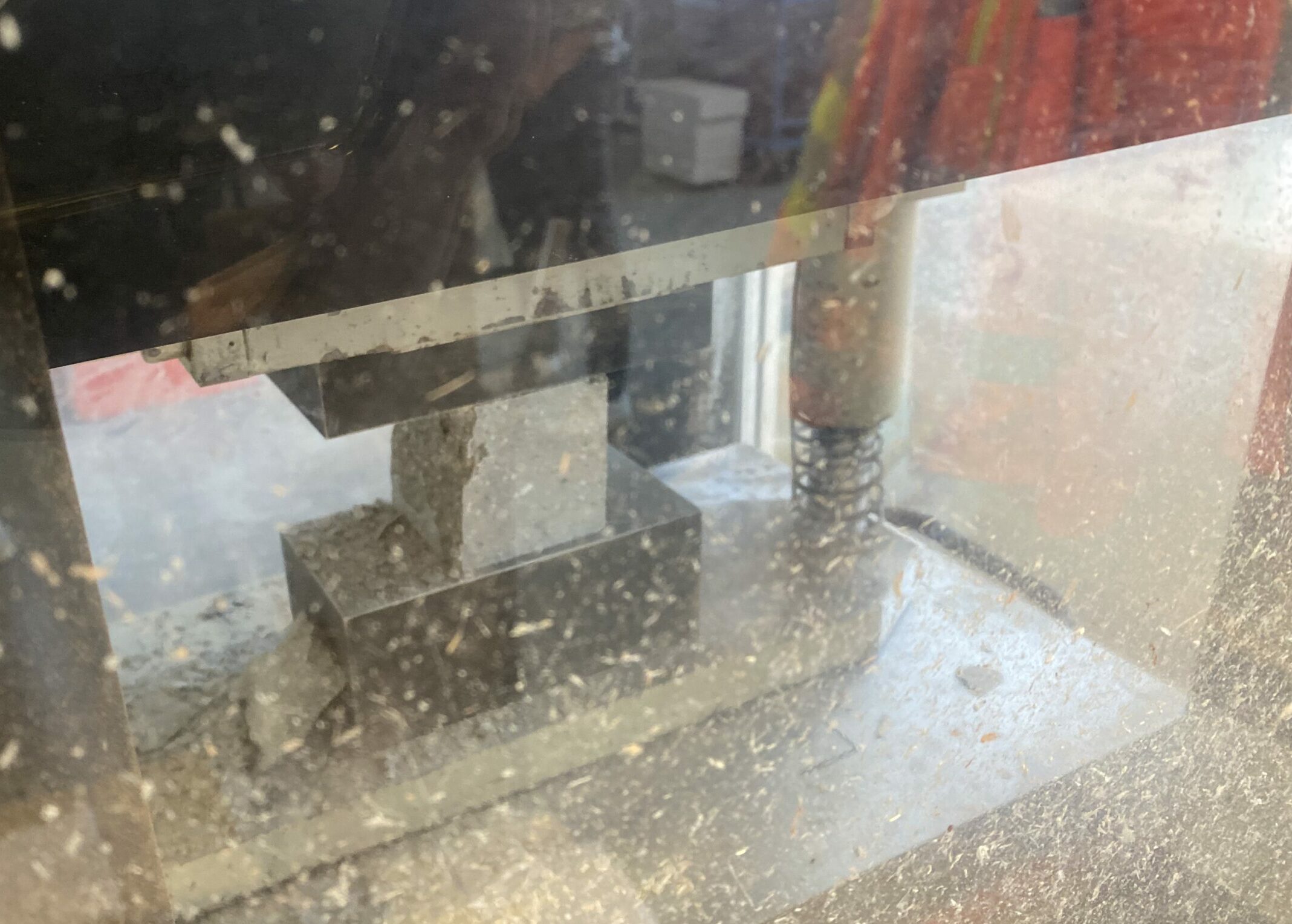

The test specimens must be placed centrically in the testing machine to achieve uniform load application.

The specimens are now to be loaded uniformly until fracture at a test speed of (1 + 0.5) MPa/s. The test specimens are then to be tested at a test speed of (1 + 0.5) MPa/s. The uniaxial compressive strength R (MPa) is calculated from the determined test load F (specified with an accuracy of 10 KN) and the cross-sectional area A (mm²). The test result is given with an accuracy of 1 MPa.

The test results determined in this way shall be summarized in a test report. This must also include statements on the standard deviation and the lower expected value of the compressive strength. The calculations of these parameters can be found in Annex C of the above-mentioned test standard.

Further information

If you have any further questions or would like individual support for your project, please feel free to contact us at any time via our contact form or send us a message to mail@besco-gmbh.de. We will get back to you shortly.

Further exciting content awaits you in upcoming articles in the INFO series on natural stone testing.

We would be happy to inform you about the latest

topics and innovations relating to natural stone.

ARTICLES ABOUT THIS TOPIC

reading time – 8 min

reading time – 5 min

reading time – 5 min

reading time – 4 min

reading time – 3 min

reading time – 5 min

reading time – 5 min

reading time – 4 min

reading time – 2 min